Preparing the mounting surface — flush mounting

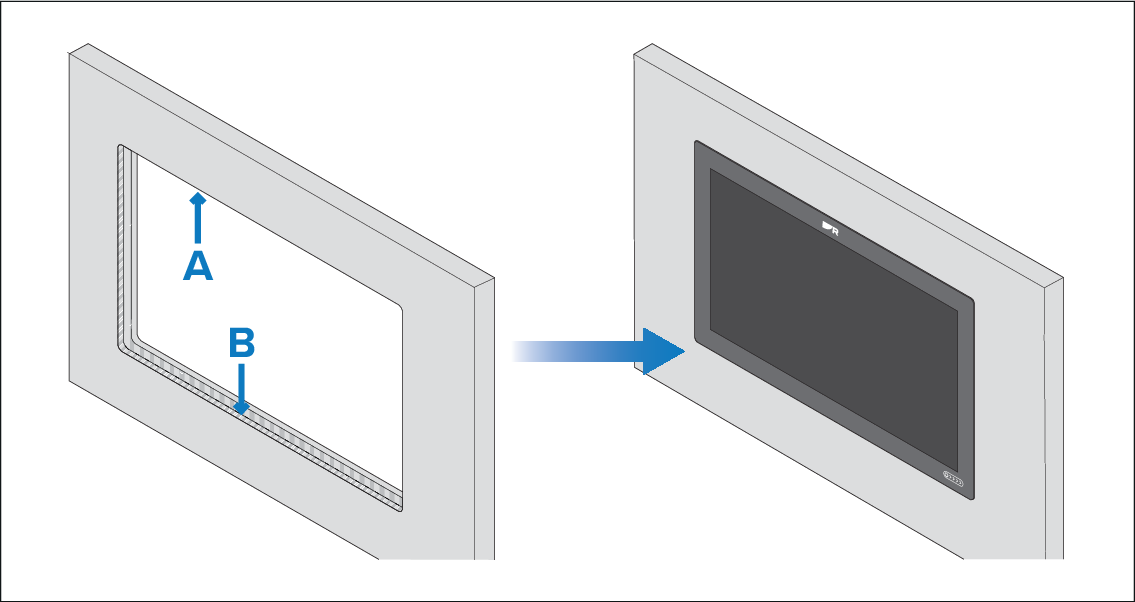

Flush mounting requires the same cut out hole as surface mounting and an additional rebate around the edge of the cut out. When the display is flush mounted, the glass will be flush with the mounting surface.

The following procedure is for preparing the mounting surface for flush mount installations. For surface mounting details refer to: Preparing the mounting surface — surface mounting

Before preparing the mounting surface ensure that:

Your selected location meets the location requirements. For details refer to: Location requirements

You have identified cable connections and the route that the cables will take.

Installation Flush mountingFlush mounting

A — Cutout (when flush mounting the cut out will be the same size as for surface mounting.

B — Flush mounting requires an extra rebate to recess the display fully in the mounting surface.